LIDAR is a great, practical, cost-effective and high quality method of collecting wind data for wind farm development, operational wind turbine performance investigation and wind energy research studies, both onshore and offshore.

LIDAR profile data can be visualised neatly in the form of video showing the variation of wind conditions such as wind speed and direction with height or LIDAR range. This is especially useful for understanding variation of wind conditions across large rotors, or in complex terrain where wind shear and wind veer may be abnormal.

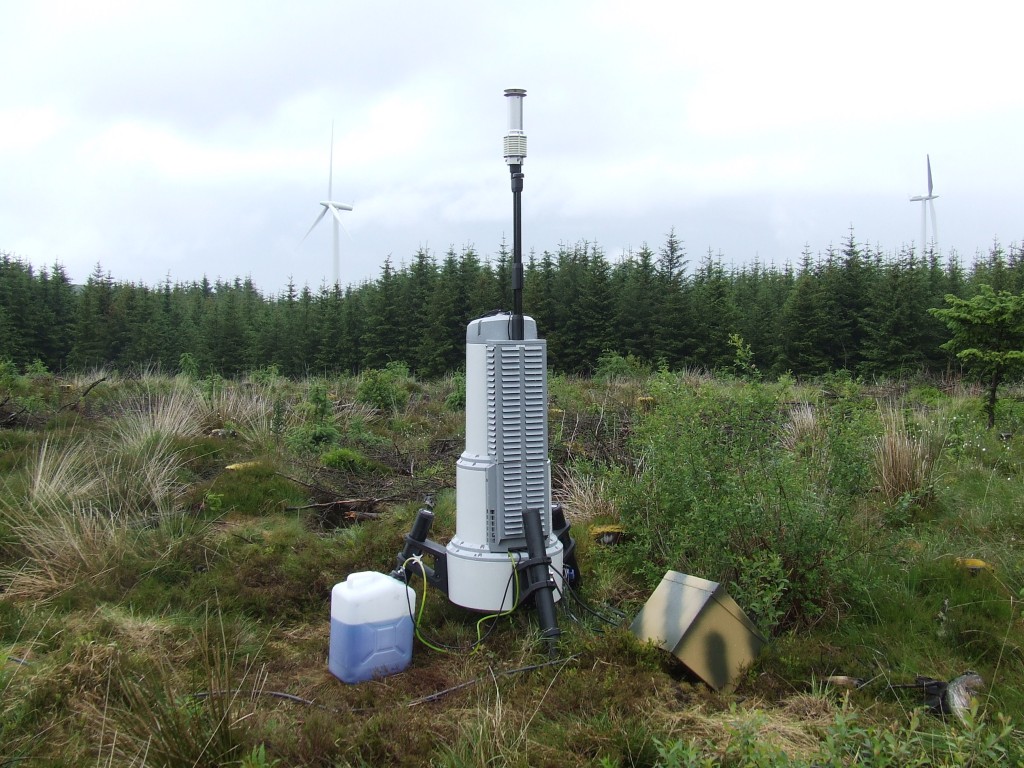

Wind Farm Analytics possesses direct practical experience of multiple LIDAR deployments and covering all aspects including project design, project management, stakeholder consultation, physical deployment and alignment, ground breaking data analysis and reporting.

Ground based upward looking LIDAR was first used by the wind industry during project development in a similar way to meteorological masts but with added portability allowing consecutive dataset collection in multiple locations. Wind Farm Analytics is able to advise and project manage such deployment for your development.

Certain innovative thinkers on the operational side of the industry quickly realised that this technology is supremely beneficial to wind turbine performance investigation where power curve analysis has highlighted possible suspect cases on operational wind farms. Wind Farm Analytics recommends this technology for engineering root cause analysis and independent cross checking of suspect wind turbine performance. This can give confidence and additional independent evidence that true underperformance is occurring allowing positive engagement with the wind turbine supplier in order to rectify the problem where possible (increasing your future production revenue and feeding back lessons learnt into future development projects) or make a performance warranty claim where appropriate.

LIDAR equipment can be deployed by just two people and does not require the same level of logistical and planning input as for meteorological masts. Moreover this laser based wind measurement technology is non-invasive within the system it is measuring – in other words it measures the wind conditions without changing them, whereas met masts are themselves an obstacle to the wind flow and will alter that wind flow. Met mast instruments often have blind spots whereas a LIDAR does not. Another advantage of LIDAR is that it can simultaneously collect data at a large number of different heights providing much more information about the wind flow across the whole wind turbine rotor area. The extent of measurement is generally much higher than existing met masts which is important for the latest generation of very large turbines extending significantly above 100m in height.

The established ground based LIDAR is now being complemented by nacelle based forward looking systems which have the potential to transform the wind industry. These systems have the advantage of always measuring wind conditions upwind from the turbine since they are mounted directly on the nacelle/rotor system and yaw into the wind along with that system. The wind measurements are upwind of the rotor giving a true measurement of incident wind conditions unaffected by passage of the rotor or bow/nacelle affects which are a major influence and source of uncertainty on existing nacelle based measurement anemometers. Wind Farm Analytics believes that in future all wind turbines may have fitted their own forward looking nacelle based LIDAR. Wind Farm Analytics knows how to quantify the numerous direct and indirect benefits of nacelle based forward looking LIDAR and we invite all large fleet operators, wind turbine manufacturers, wind turbine test beds, research groups and LIDAR manufacturers to obtain our consultancy on how to increase the benefits of this technology.